DesignGear –

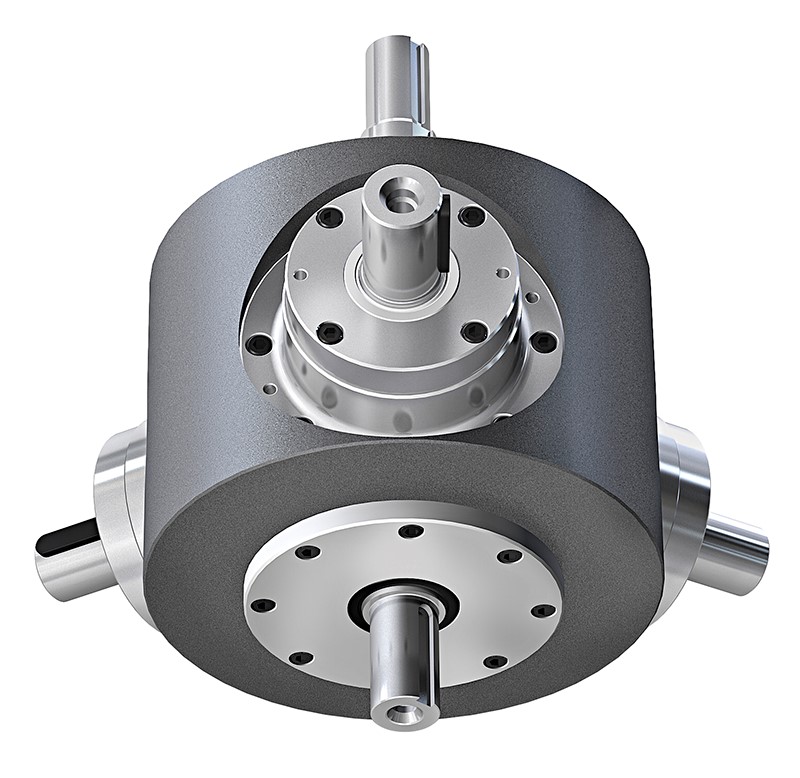

The customised special gearbox

For everyone who expects more: special gearboxes from the specialist.

We provide gear solutions for your individual performance requirements, including designs, tooth developments, prototype manufacture, extensive tests and documentation, right up to the delivery of the series.

Our customised gears include:

- Single-stage bevel gears as control or reverse gears

- Labyrinth-sealed gears with a degree of efficiency of > 98%

- High temperature gears for ambient temperatures of up to 300°C

- Saw drive gears

- Test station gears with output speeds of up to 12000 min-1

- Double gears with two transmission ratios

- Robotic gears

- Spur gears

- High precision gears

- And much more